Printouts Are Blank/Blurry or Fuzzy/Inaccurate or Bleeding Colors/Streaks or Lines

Printouts Are Blank/Blurry or Fuzzy/Inaccurate or Bleeding Colors/Streaks or Lines

Although some air may enter the ink tube, it is not a malfunction. No problem if the nozzle check pattern is printed correctly.

-

Check1 Make sure joint button is not lifted up.

Push the print head locking cover to make sure the print heads are installed properly.

Next, push the joint buttons firmly to the end.

Important

Important-

Remove the orange label and the protective tape of the print head to install it.

-

-

Check2 Check paper and print quality settings.

-

Check3 Print a nozzle check pattern and clean the print head if necessary.

-

Step 1 Print the nozzle check pattern.

If the pattern is not printed correctly, check if the ink tank for the problem color is empty.

if the ink tank is not empty, go to the next step.

-

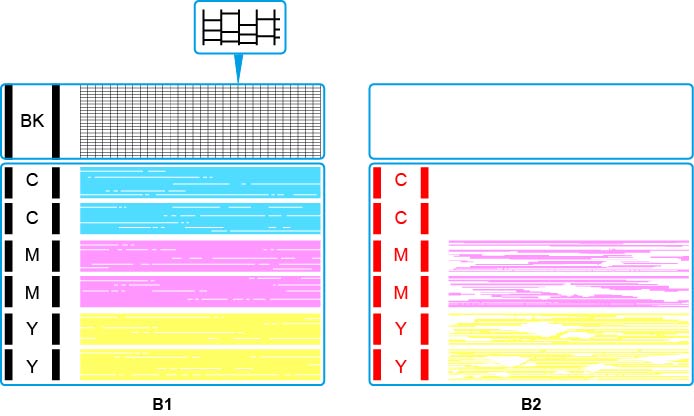

Step2 Check the printed nozzle check pattern.

-

If the nozzle check pattern is similar to B1:

If the nozzle check pattern is similar to B2:

-

Note

Note-

From the printer

-

From the computer

-

For Windows:

-

For macOS:

-

-

-

-

Step3 Clean the print head.

After cleaning the print head, print the nozzle check pattern and check the result.

-

From the printer

-

From the computer

-

For Windows:

-

For macOS:

-

If it does not improve, clean the print head again.

If it still does not improve, go to the next step.

-

-

Step4 Clean the print head again.

After cleaning the print head again, print the nozzle check pattern and check the result.

If it still does not improve, go to the next step.

-

Step5 Clean the print head deeply.

After cleaning the print head deeply, print the nozzle check pattern and check the result.

-

From the printer

-

From the computer

-

For Windows:

-

For macOS:

-

If it does not improve, turn off the printer, wait for more than 24 hours, and go to the next step.

-

-

Step6 Clean the print head deeply again.

After cleaning the print head deeply again, print the nozzle check pattern and check the result.

-

From the printer

-

From the computer

-

For Windows:

-

For macOS:

-

If it still does not improve, go to the next check.

-

Check4 Perform ink flush.

- How to Perform Ink Flush

If performing an Ink Flush does not improve the print results of the nozzle check pattern, replacing the print head may resolve the issue.

For details, see here.

Note

Note

-

To minimize image issues, we recommend printing once a week.

Check5 When an ink tank runs out of ink, refill the ink tank.

If the remaining ink level is below the lower limit line (A), refill the ink tank with the corresponding color of ink.

If you use the printer until the ink tank becomes empty, perform ink flush after refilling the ink tank.

Check6 When using paper with one printable surface, check the correct printable side of the paper.

Printing on the wrong side of such paper may cause unclear prints or prints with reduced quality.

When you load paper on the rear tray, load paper with the printable side facing up. When you load paper in the cassette, load paper with the printable side facing down.

Refer to the instruction manual supplied with the paper for detailed information on the printable side.

-

When copying, see also the sections below:

-

Check7 Is platen glass or glass of ADF dirty?

Clean the platen glass or the glass of ADF.

Note

Note-

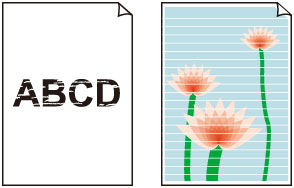

If the glass of ADF is dirty, black streaks appear on the paper as shown below.

-

-

Check8 Make sure original is properly loaded on platen or ADF.

When you load the original on the platen, load it with the side to be copied facing down.

When you load the original on the ADF, load it with the side to be copied facing up.

-

Check9 Is copy source a printed paper by printer?

If you use a printout done by this printer as the original, print quality may be reduced depending on the condition of the original.

Reprint from the computer if you can reprint from it.

-

Note

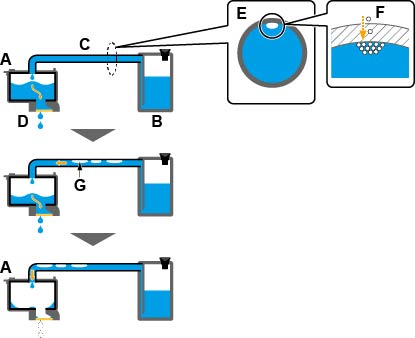

Note- Air may naturally enter the Print Head (A), which ejects ink, and the Tube (C), which connects it to the Ink Tank (B).If this air is carried to the head and accumulates there, it may become difficult to dispense the Ink (D).

- The cross-section of the Tube (E) shows that a small amount of air (F) enters.This minute amount of air is carried along with the ink during printing and does not affect the result. However, if the printer is not used for a long time, large bubbles (G) form.Large air bubbles are transported to the Print Head. When the amount of air inside the Print Head (A) increases to a certain level, the flow of ink becomes restricted, resulting in blurred images or blank pages being ejected.